Why Gear Motors Are Preferred in Industrial Automation

Industrial automation has transformed the way modern factories operate. From conveyor systems and packaging lines to robotics and material handling equipment, automation demands precision, reliability, and efficiency.

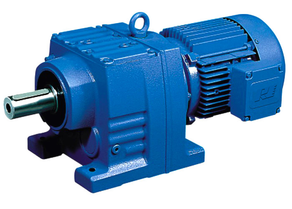

At the heart of many automated systems lies one critical component the gear motor.

A gear motor combines an electric motor with a gearbox to deliver controlled speed and high torque in a compact form. Due to these advantages, gear motors have become the preferred choice across almost every industrial automation application.

This article explains why gear motors are preferred in industrial automation, how they improve performance, and what makes them indispensable for modern industries.

Understanding What a Gear Motor Is

A gear motor is an integrated unit consisting of:

An electric motor

A gear reducer (gearbox)

The gearbox reduces motor speed while increasing torque, allowing machines to operate efficiently under varying load conditions.

Whether it is a DC gear motor or an AC gear motor, this combination offers better control than a standalone motor.

In industrial automation, where machines must perform repetitive tasks with accuracy, gear motors provide the perfect balance between power, speed, and control.

The Role of Gear Motors in Industrial Automation

Automation systems rely on synchronized motion, controlled speed, and consistent torque output. A standard motor running at high speed is often unsuitable for direct industrial use. This is where a high torque gear motor becomes essential.

Gear motors are used in:

Conveyors

Automated assembly lines

Packaging machines

Robotics and pick-and-place systems

Mixers, crushers, and material feeders

Their ability to deliver torque at low speeds makes them ideal for automation-driven machinery.

High Torque Output for Heavy Industrial Loads

One of the main reasons a gear motor is preferred in industrial automation is its high torque capability.

Automation equipment often needs to:

Start under heavy load

Operate continuously

Handle variable load conditions

A high torque gear motor ensures smooth startup and stable operation without stalling. This is particularly important in conveyor systems, lifting mechanisms, and process equipment where torque demand is high.

Without a gear motor, achieving this torque would require a much larger and less efficient motor.

Precise Speed Control for Automated Processes

Automation demands precision. Machines must operate at specific speeds to maintain product quality and production consistency.

A gear motor provides:

Reduced output speed

Stable rotational movement

Minimal speed fluctuations

This makes gear motors perfect for applications such as packaging lines, filling machines, and textile automation, where even minor speed variations can affect output quality.

When paired with controllers or drives, both AC and DC gear motors offer exceptional speed regulation.

Compact Design Saves Space in Automation Systems

Modern industrial automation focuses on compact and modular machine design. Space constraints are common, especially in automated production lines.

A gear motor integrates the motor and gearbox into a single unit, offering:

Reduced installation space

Simplified mounting

Cleaner machine layout

Compared to separate motor and gearbox assemblies, a gear motor reduces complexity and improves overall system design efficiency.

Energy Efficiency and Cost Savings

Energy consumption is a major concern in industrial automation. Running oversized motors leads to wasted energy and higher operating costs.

A gear motor operates closer to its optimal efficiency range by:

Matching torque and speed requirements

Reducing mechanical losses

Improving load handling efficiency

Although gear motor price may appear higher than a standard motor initially, the long-term savings in energy, maintenance, and downtime make it a cost-effective solution.

Reliability and Long Service Life

Automation systems often run continuously, sometimes 24/7. Equipment failure can lead to costly downtime and production losses.

Gear motors are designed for:

Continuous duty operation

High mechanical strength

Long service life

Reputable gear motor manufacturers use hardened gears, precision bearings, and robust housings to ensure reliability even in harsh industrial environments.

This reliability is one of the biggest reasons automation engineers trust gear motors.

Reduced Maintenance Requirements

Maintenance is a critical factor in industrial automation planning. Frequent maintenance disrupts production schedules and increases operational costs.

A gear motor requires:

Minimal lubrication maintenance

Fewer mechanical components compared to belt or chain drives

Less alignment effort

This simplicity makes gear motors ideal for automated systems where maintenance access may be limited.

Versatility Across Automation Applications

Another reason the gear motor is preferred is its versatility. Different types of gear motors are available to suit specific automation needs:

Helical gear motors for smooth and quiet operation

Worm gear motors for compact and right-angle applications

Planetary gear motors for high precision and torque

DC gear motors for variable speed and low-voltage applications

This flexibility allows automation designers to select the right gear motor for each machine function.

Importance of DC Gear Motors in Automation

A DC gear motor plays a crucial role in automation systems requiring:

Precise speed control

Quick response

Low-voltage operation

DC gear motors are commonly used in:

Robotics

Automated guided vehicles (AGVs)

Control panels

Small automation modules

Their ability to deliver consistent torque at low speeds makes them ideal for advanced automation tasks.

Gear Motor Price vs Performance Value

Many buyers focus only on gear motor price during procurement. However, in industrial automation, value matters more than initial cost.

A quality gear motor offers:

Higher efficiency

Lower maintenance cost

Reduced downtime

Longer operational life

Choosing a low-cost gear motor without considering application suitability often leads to frequent failures and higher long-term expenses.

This is why experienced automation engineers prioritize performance and reliability over short-term cost savings.

Role of a Reliable Gear Motor Manufacturer

Selecting the right gear motor manufacturer is as important as choosing the motor itself. A trusted manufacturer provides:

Application-specific motor selection

Quality-tested components

Compliance with international standards

Technical support and after-sales service

In industrial automation projects, working with an experienced gear motor manufacturer ensures smoother integration and long-term operational stability.

Integration with Smart Automation Systems

With the rise of Industry 4.0, gear motors are evolving to support smart manufacturing.

Modern gear motors can be integrated with:

Sensors for condition monitoring

Variable frequency drives (VFDs)

Automation control systems

This allows predictive maintenance, reduced downtime, and improved production efficiency making gear motors future-ready for smart factories.

Why Gear Motors Outperform Standard Motors in Automation

Compared to standard motors, gear motors offer:

Better torque control

Lower operating speeds without loss of power

Compact and integrated design

Improved reliability

These advantages make the gear motor the preferred choice for almost every industrial automation application.

Conclusion: Gear Motors Are the Backbone of Industrial Automation

The increasing adoption of automation across industries has made the gear motor an essential component of modern machinery.

From delivering high torque at low speeds to ensuring precision, efficiency, and reliability, gear motors meet every critical requirement of industrial automation.

Whether it is an AC gear motor or a DC gear motor, these systems provide superior performance compared to conventional motors.

While gear motor price may vary depending on type and application, the long-term benefits far outweigh the initial investment.

By choosing the right gear motor and partnering with a reliable gear motor manufacturer, industries can achieve higher productivity, lower operating costs, and future-ready automation systems.

Comments

Post a Comment